Dynamic coal flow balancing by e.con

Innovations are essential for keeping ahead of competition at all times. Only those at the leading edges of technology can maintain a primary role in the markets they serve. Since our foundation we have also committed ourselves to this goal.

Environmental aspects

Nowadays, in times of global warming, innovative environmentally friendly technologies are becoming increasingly important.

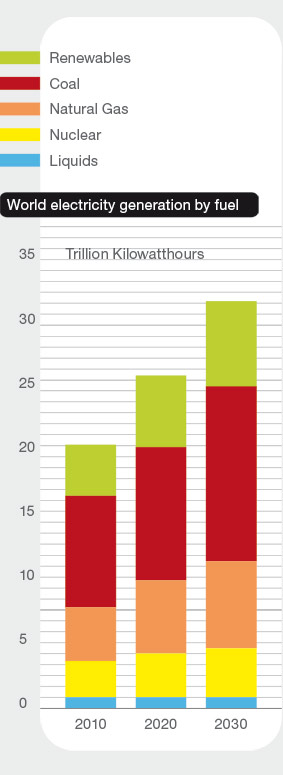

Global warming is the increase in the average temperature of the Earth's near-surface air and oceans and its projected continuation. The Intergovernmental Panel on Climate Change (IPCC) concludes that most of the observed temperature increase is caused by rising concentrations of greenhouse gases. Their increase results from human activity such as fossil fuel burning and deforestation.The main greenhouse gases in the Earth's atmosphere are water vapour, carbon dioxide, methane, nitrous oxide, and ozone. The available options to cut back further emissions are mitigation, adaptation to reduce the damage caused by warming, and geoengineering. However, today's world population is growing constantly as is the demand for energy. The current prediction is an increase in energy consumption by about 50% in the next 20 years. Non-renewable sources will continue to provide the most energy.

Predicted electricy generation by fuel in the next 20 years, based on the information of the United States Energy Information Administration (EIA).

The dilemma of greenhouse gas emissions on the one hand and power demand on the other, coal fired power plants become of enormous importance. Therefore e.con and partners have developed comprehensive solutions for power plants to contribute their technology toward a better environment.

The objectives for a more environmentally – friendly operation of coal fired power plants while still supplying existing power demands are:

High availability

High efficiency

High flexibility

Low emissions

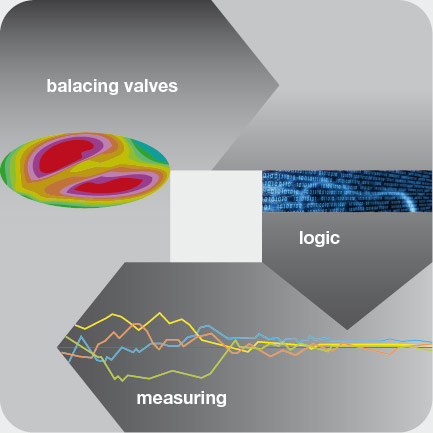

One key word for improvement is the conversion of coal fired power plants into fuel injection type units. This conversion requires the corresponding instrumentation to continuously monitor the pulverized coal flow to the individual burners as well as a device that is able to control the coal flow at any given time. Both technologies are available today.

On the flow monitoring side we either apply an acoustic based technology or the latest technology based on electromagnetic principles and on the fuel flow control side we utilize the PBG-1 Valves. By linking all techniques into a controlled loop operation we enter the world of dynamic coal flow balancing and gain the conversion into fuel-injected power plants.