Saving potentials

Optimization of fuel and air distribution in a coal fired utility boiler is one way to reduce the consumption of fossil fuel and lowering CO2 emissions correspondingly.

The technical feasibility of real time coal flow distribution measurement, and the benefits of coal flow balancing have been demonstrated. The differences between pre- and post optimization were measured by comprehensive testing.

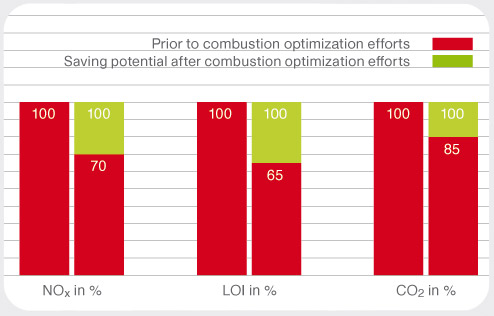

Combustion optimization by dynamic coal flow balancing may result in:

- reduction of Nox and CO2

- reduction of excess air

- reduction in LOI

- reduction in opacity events

- reduction in water wall wastage

- reduction in auxiliary power

- more balanced furnace temperatures

- extended lifetime of materials (less maintenance)

Thus gaining:

- increased efficiency up to 0,5%

- increasing availability

- financial savings up to 800.000 US$ per annum

The return of investment (ROI) period for dynamic coal flow balancing is 1-3 years